What Is a Corrugated Box?

What Is a Corrugated Box?

When planning which shipping and storage materials to invest in, you can determine whether a cardboard box vs. a corrugated box will better serve your business needs by understanding each type thoroughly. With unique features and versatility, corrugated boxes can provide companies with the care and support they need when handling their products.

Table of Contents

- What are Corrugated Boxes?

- How are Corrugated Boxes Made?

- Specifications of Corrugated Boxes

- Benefits of Corrugated Boxes

- Invest in Corrugated Boxes

What Are Corrugated Boxes?

A corrugated box is a type of box that uses corrugated — ridged or grooved — materials to create extra support and strength for shipping and storage purposes. These boxes have two components that contribute to their abilities — the liners and the medium.

The liners are cardboard or paper materials that make up the walls of a box. The medium rests between them, another paper material that a corrugator folds to create ridges or arches, called flutes, giving the box its ability to support heavier weights. The flutes use basic engineering principles to perform their purpose.

The medium and its flutes make corrugated boxes different from other box types. The flutes’ arches allow the simple paper to withstand hundreds of pounds. This box can undergo many types of customization and personalization, making it popular for many companies across industries.

How Are Corrugated Boxes Made?

Because of the unique elements that separate corrugated boxes from cardboard ones, a particular process is required to make a corrugated box. The process starts with a corrugator, which runs the liners and medium through it. The corrugator uses high-temperature steam to create the flutes and glue the peaks of the arches to the liner.

When the box has its medium, you run it through a machine that cuts the box to its desired size and specifications, scoring it where it will fold. Then, a trimmer will cut the flaps according to the box type and any necessary handles. Like cardboard boxes, you have the choice of many types of corrugated boxes, allowing you to select one that will work best for your products and purpose.

At the final stage, a folding machine bends the board along the scored lines to create the box. It applies glue to help the box hold its shape. For further customization, you can run the boxes through printing machines to add words or images to the sides, which can be powerful marketing tools for companies.

After boxes finish assembly, they can receive different coatings or finishes for additional protection and abilities. While corrugated boxes are already incredibly strong, finishes can help give them other properties they might not already have — aqueous coats can help provide further protection from dirt and wear, and ultraviolet (UV) finishes cure the box under strong UV lights to make the box more scratch-resistant.

Specifications of Corrugated Boxes

Understanding the various corrugated box specs lets you know which factors to manipulate to best protect and support your products before shipping or storing them. These boxes come with many elements you can change and customize to create the perfect package that meets your needs.

Flute Profiles

One of the essential aspects of corrugated box specs is the flute profile you choose, which caters to various strength and thickness levels:

- Flute profile A: This flute profile is the thickest model with larger arches. Boxes with this flute type will have a medium that is 4.8 millimeters thick. When running it through the corrugator, it will create a medium that has 36 flutes per foot.

- Flute profile B: The medium for this flute profile is 3.2 millimeters thick, with 49 flutes per foot. This flute profile can create very strong boxes, making them perfect for stacking on pallets or shelves in your warehouse or when you need a lot of protection in shipping.

- Flute profile C: C flute profiles are the most common type. They are versatile, allowing them to provide excellent stacking, cushioning and printing capabilities, so companies can benefit from using them for their storage or shipping needs. C flutes are 4.0 millimeters thick, with 41 flutes per foot.

- Flute profiles E and F: The E and F flute profiles drop drastically in size. E measures 1.6 millimeters thick and creates 90 flutes per foot, while F is 0.8 millimeters thick and has 128 flutes per foot. Companies can make great use of these thinner flute profiles because they can enhance printing quality and clarity, allowing you to boost your marketing efforts with your boxes.

While these are the most common types, some companies offer specialty flute profiles you can use for your specific needs. Depending on your board type, you might mix different flute profiles. Some commonly mixed profiles include B and C or E and F. If you need something smaller than the E and F profiles, you can also find N and O. They are less common, and both measure under a millimeter.

The different flute profiles add to the customization abilities of corrugated boxes. When you understand the other flute profiles and how they can benefit your goods, you can better select the suitable flutes for your needs.

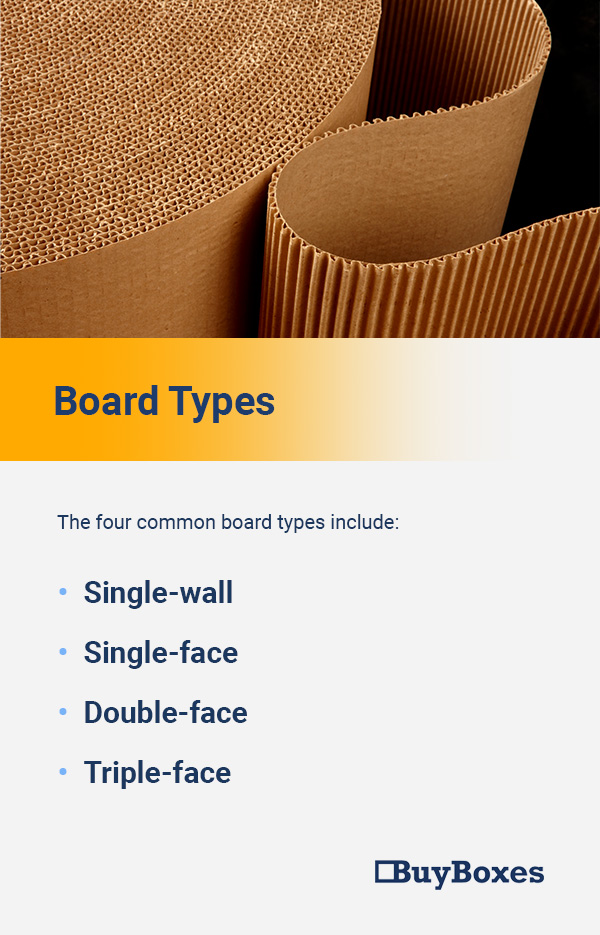

Board Types

e-Commerce is here to stay, and so is the need for creative, customized and smart packaging. Not sure where to start? Contact us with your product details, and let us come up with an unforgettable unboxing experience for your customers.

Board type is another way to change corrugated box specs and customize your boxes. The various board types can help you select the right strength and protection levels you’ll need for your products. These help corrugated boxes apply to several industries, with varying types of boards that can support different products.

The four common board types include:

- Single-wall: Single-wall corrugated board involves only one liner layer attached to one medium layer. Businesses often use this type for protective cushioning in boxes. Many places sell it by the roll, offering companies bulk packaging material. Corrugated materials are easy to recycle, making single-wall corrugated boards attractive to businesses looking for eco-friendly packaging options.

- Single-face: The single-face corrugated board is the most common type used for corrugated boxes. It uses one sheet of fluted medium between two liners — one interior and one exterior. This type provides standard strength and protection, allowing it to have applications across several industries.

- Double-face: Double-face boards incorporate two corrugated sheets situated between three liners. The extra layer is the interior, resulting in two interior liners and one exterior. The other mediums and liners create a stronger box that can support heavier products or provide you with more protection.

- Triple-face: This board type is the strongest available. It includes three corrugated sheets between four liners. Because of its optimized strength, many industrial companies use them when shipping or storing heavy machinery parts. Their extra protection and cushioning make them ideal for shipping produce, allowing the food to arrive at its final destination with minimal bruising.

The different board types can ensure you can find a corrugated board that can protect and support your products, regardless of your industry. Whether you need extra cushioning or strength, your products can receive the care they need with the different board types.

Board Grades

Board grades can help you determine the board’s quality and how much pressure it can withstand in different situations. You can use two tests to measure this factor, each offering additional information about your boxes — the Mullen Test and the Edge Crush Test (ECT).

The Mullen Test will apply pressure to the flat surface of the liner and measure how much weight it can take before bursting, puncturing, rupturing or overall falling apart. It measures how much support the arches from the flutes can provide.

This test is essential if you are searching for a highly resistant box that can ensure your goods stay safe during shipping. When you know a box’s Mullen score, you can better understand the conditions your box can withstand during travel.

Boxes that undergo the Mullen Test will receive a number score, followed by a pound (#) symbol. This score signifies how much force the box can maintain before failing. For example, a box with a score of 200# can hold 200 pounds of force per square inch.

On the other hand, ECT is a vertical test that applies pressure to the edge of the box or the part with the flutes exposed and not receiving the support of the arches. While the Mullen Test tests flute strength, this test can help you understand how well your box can function in various situations.

Boxes in shipment or storage can undergo extreme conditions, including changes in humidity or temperature, storage stacking patterns and length and pressure. The ECT can help you find a resilient box that meets your performance standards.

Like the Mullen Test, boxes will receive an ECT score. This score will reflect how many pounds of pressure the box was able to withstand before getting crushed. For example, a box with a 55 ECT score will be able to maintain 55 pounds of pressure.

4 Benefits of Corrugated Boxes

Knowing the benefits of this box type can help you understand the reasons to use a corrugated box. The benefits can highlight what makes corrugated boxes unique and areas where you can improve your business habits.

If you are pitching ideas to managing or executive teams, you can point out these benefits in your presentation to help your audience understand why your company should make the switch to corrugated boxes.

1. Custom Solutions

Corrugated boxes offer increased flexibility and versatility for companies that need more specialized custom solutions. This box type can allow you to select various features depending on your needs, from the specs we listed here to personalized marketing needs. You can customize your corrugated boxes to meet multiple functions.

Different board grades, types and flute profiles can deliver additional capabilities. Thicker flutes, higher grades and board types can offer increased protection and strength, allowing you to create a box that can withstand your shipping conditions or support even your heaviest or more fragile products.

Further, you can print images and words on the exterior liners of corrugated boxes. This custom capability can allow you to strengthen your marketing efforts, especially if you are an e-commerce company or ship goods to your online audience. Choose colors, fonts, symbols and logos that meet your branding standards, creating a look your customers will recognize every time.

2. Eco-Friendly

Many customers and companies value green initiatives and the dedication to reuse and recycle materials. Because of their strength, you can often reuse corrugated boxes several times. However, after they reach the end of their life span, you can also recycle them.

Corrugated boxes often contain recycled materials, with around 50% of the box coming from other recycled boxes. After recycling a corrugated box, you can recycle that material around seven to 10 times to create new boxes or other paper products. Further, around 96% of all boxes get recycled, making it an environmentally-friendly industry that helps keep waste out of landfills.

3. Pleases Customers

When considering different box types, you should also think about the customer experience they can provide. Corrugated boxes can make your customers happy with your company because the additional protection and strength can keep their goods safe. You can build a trusting and reliable reputation with corrugated boxes.

Further, the increased customization can help you make a unique unboxing experience. Designing a beautiful box can allow your customers to recognize when their packages have arrived right away, creating a sense of excitement as they prepare to unpack their product.

4. Cost-Effective

Because corrugated boxes are easy to recycle and reuse, you can save money on materials. You can reuse your warehouse boxes until they wear through, ensuring you can get the most out of your investment. However, you can also lower your costs when buying new boxes by choosing those made from recycled materials since that can help bring the price down.

While corrugated boxes are excellent choices for lowering investment expenses, you can also use them to reduce supply chain costs. Using corrugated boxes for heavier or fragile goods can ensure they stay safe during transit and arrive in their best condition. These boxes can help save money on covering the costs of damages and maintaining a happy customer base.

Invest in Quality Corrugated Boxes From BuyBoxes

From increased protection to environmentally-friendly solutions, corrugated boxes can offer several benefits and functions for businesses. You can customize many of their features, allowing you to find the level of protection and strength you need for your products or create an aesthetic that meets your marketing goals and gets your customers excited about receiving packages.

At BuyBoxes, we understand the importance of customization and flexible solutions. With over 75 years of experience, we have curated a services system to help you get the most from your corrugated box investment. We offer custom engineering services, where you can work with a team of designers and engineers to create the box that will work best for your business needs.

Additionally, we dedicate ourselves to sustainability, helping your company select packaging materials you can recycle and keep out of landfills. Partnering with BuyBoxes is a great option for companies that value green solutions or businesses that want to make efforts to become more eco-friendly.

Contact BuyBoxes today and discover how our services can help you better store and ship your products.

What Is a Corrugated Box?

What Is a Corrugated Box?